Have you ever wondered why salmon caviar is an expensive product? The answer lies in complex and multi-stage production technology, the first stage of which is the extraction of caviar. Then the caviar is sorted, processed, and salted. The filling process ends the caviar production.

Extraction of red caviar

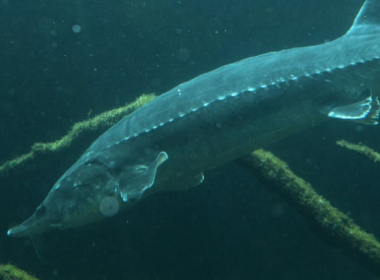

The main places for catching red caviar are the Pacific Ocean, the Okhotsk, and Bering seas. Fishing has developed in Russia (Kamchatka, Sakhalin, and Khabarovsk Territory) and the USA (Alaska). Fishing is carried out with the help of trawls, fixed seines, nets, and other gear that can be equipped with salmon fishing vessels. The fishing season for fishing is from June to October.

As a rule, catching is carried out in the coastal zone, where fish accumulate, swimming in rivers for spawning. Because of it, the process of obtaining caviar is greatly facilitated. Nevertheless, there are certain difficulties - it is necessary to get caviar within 2-3 hours so that it does not have time to deteriorate. It is impossible to hesitate with salting and packaging the final product. If salting is not carried out, then the caviar is frozen, which allows to significantly increase the period of its storage.

How caviar is made

It is believed that the faster the caviar is extracted from the fish, the better it's quality. Therefore, cutting is carried out directly on the ship: on a trawler or at the so-called "floating factories". The caviar is washed with seawater and sorted, and the fish is subject to further processing, while the insides are thrown overboard. Caviar from different fish should not be mixed, therefore, at the cutting stage, the ovaries are sorted by salmon species. Ovules are natural film shells that prevent eggs from moving freely inside the fish.

Caviar grain: best quality

To get rid of roes, connective tissue, and low-quality grain, they use screens - special grates through which caviar is sifted with the help of vibration. As a rule, caviar passes through two machines and then is poured over an inclined gauze, which allows removing residual contamination. After rocking for cleansing, the caviar is poured with brine - a concentrated saline solution. Simultaneously with salting, the final cleaning of the grains takes place. The caviar is placed in a saline solution in a ratio of 1: 3 (caviar/brine). The permissible salt content in caviar is from 3 to 7%.

After 10-20 minutes of salting, the caviar is fed into a centrifuge, which allows you to extract excess liquid from the final product. Then quality control is carried out, after which a preservative is added to the caviar. The resulting product is packaged in small plastic containers. They are sealed and labeled to be sent to the factory for packaging.

How to choose the best caviar

The more you know about red caviar and the basics of its production, the better product you can choose for yourself. The production of caviar requires a scrupulous approach and high labor costs. To enjoy the taste of first-class caviar, strict adherence to technology and the hard work of a large number of people are necessary.

Our online store IKRiNKA.de offers first-class quality red and black caviar at attractive prices. You can order caviar at any time convenient for you. We deliver all over Europe.